Logistics is a critical component of any supply chain, involving the movement, storage, and management of goods from point A to point B. In recent years, the power of robotics and automation has been transforming the logistics industry, revolutionizing processes, and improving efficiency. In this article, we will explore the various applications and benefits of robotics and automation in logistics.

Warehouse Automation

One of the areas where robotics and automation have made significant advancements is in warehouse operations. Automated systems, such as conveyor belts, robotic arms, and automated guided vehicles (AGVs), can handle tasks such as picking, packing, sorting, and transporting goods within a warehouse.

Robotic arms equipped with computer vision technology can identify and pick items from shelves with precision and speed. AGVs, guided by sensors and software, can navigate through the warehouse, transporting goods from one location to another. These automated systems not only reduce manual labor but also improve accuracy, speed, and overall efficiency in warehouse operations.

Inventory Management

Effective inventory management is crucial for the smooth functioning of logistics operations. Robotics and automation play a vital role in this aspect as well. Automated systems can accurately track inventory levels, monitor expiration dates, and even replenish stock automatically.

For example, automated robots with RFID technology can scan and track inventory in real-time, providing accurate information about stock levels and locations. This allows logistics managers to optimize inventory levels, reduce stockouts, and improve overall supply chain visibility.

Last-Mile Delivery

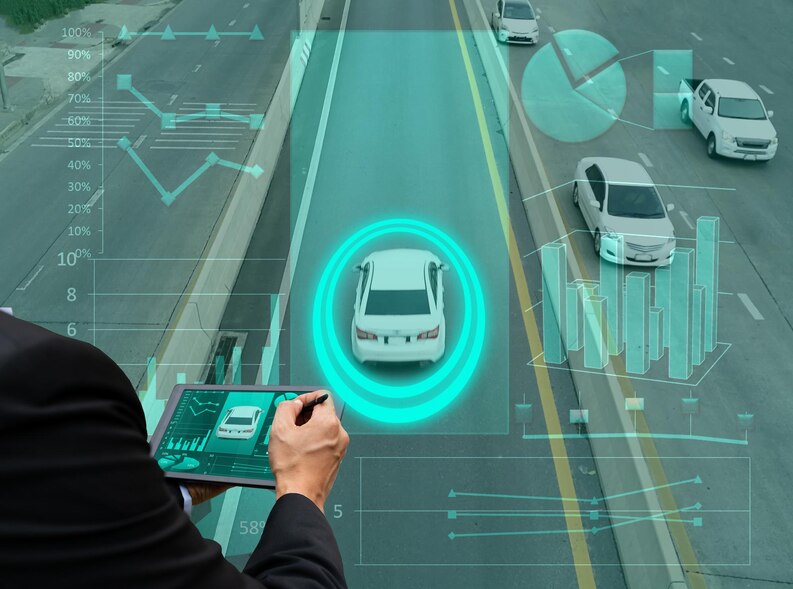

Last-mile delivery, the final leg of the delivery process from a distribution center to the customer’s doorstep, is often the most challenging and costly part of the logistics journey. Robotics and automation are being leveraged to address these challenges and improve last-mile delivery efficiency.

Delivery drones and autonomous delivery vehicles are being tested and deployed in certain areas to deliver packages quickly and efficiently. These technologies can navigate through traffic, avoid obstacles, and deliver packages to customers’ homes or businesses. Automated lockers and smart parcel management systems are also being used to provide convenient and secure delivery options for customers.

Supply Chain Optimization

The complex nature of supply chains requires effective coordination and optimization of various processes. Robotics and automation are instrumental in achieving this optimization by providing real-time data, predictive analytics, and process automation.

Automated systems can collect and analyze vast amounts of data related to logistics operations, including transportation routes, delivery times, and warehouse capacity. This data can be used to optimize routes, reduce transportation costs, and improve overall supply chain efficiency.

Furthermore, robotics and automation enable process automation, reducing human error and enhancing speed and accuracy. For instance, automated systems can generate and process shipping labels, track shipments, and even schedule transport routes, minimizing manual intervention and streamlining operations.

Safety and Risk Mitigation

Safety is a critical concern in logistics operations. Robotics and automation can contribute to enhancing safety and risk mitigation in various ways. Automated systems can handle hazardous materials or heavy loads that may pose risks to human workers. This reduces the likelihood of accidents and injuries.

Additionally, automation can provide real-time monitoring of equipment and assets, identifying potential issues before they cause disruptions or breakdowns. Predictive maintenance and remote monitoring capabilities enable proactive maintenance and reduce downtime.

Conclusion

The power of robotics and automation in logistics is transforming the industry, revolutionizing warehouse operations, inventory management, last-mile delivery, supply chain optimization, and safety. By leveraging these technologies, logistics companies can improve efficiency, reduce costs, enhance customer satisfaction, and stay competitive in a rapidly evolving market.

While robotics and automation continue to advance, it is important to note that human workers still play a vital role in logistics operations. Collaboration between humans and automated systems is key to harnessing the full potential of these technologies. As robotics and automation continue to evolve, logistics professionals must adapt and embrace these advancements to unlock the full potential of their operations.