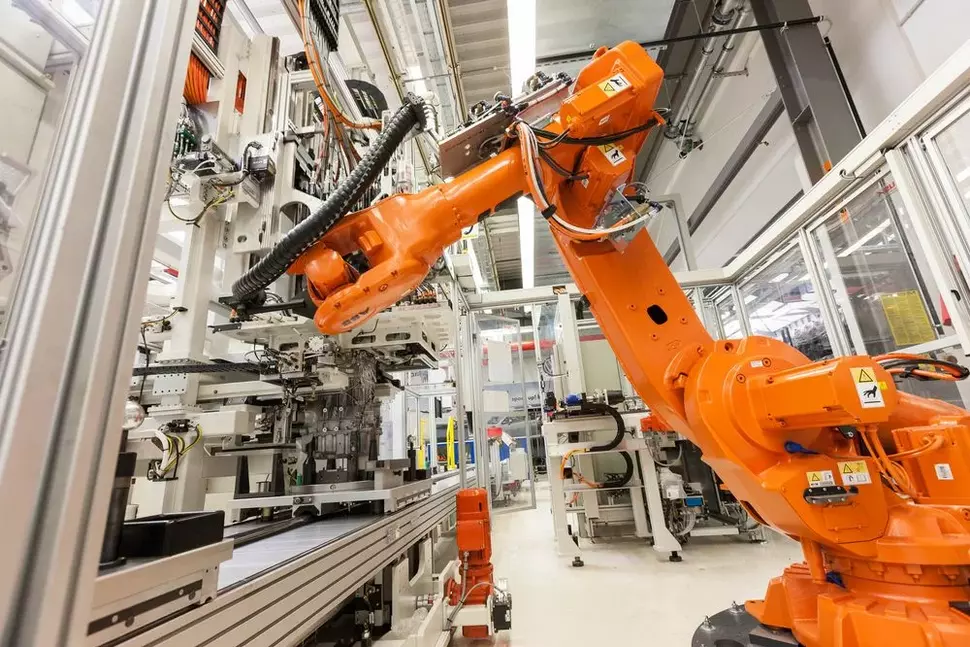

In the field of heavy load transportation, workplace safety is of utmost importance. The introduction of smart robots has significantly enhanced safety measures in this industry. These advanced robotic systems are equipped with intelligent features and cutting-edge technology that not only improve efficiency but also minimize risks and ensure the safety of workers. In this article, we will explore how smart robots enhance workplace safety in heavy load transportation.

Automated Material Handling

Smart robots are capable of handling heavy loads with precision and accuracy, eliminating the need for manual lifting and carrying. This automation reduces the risk of musculoskeletal injuries that can occur due to heavy lifting. By taking over the task of material handling, smart robots minimize the physical strain on workers and help prevent accidents and injuries caused by lifting heavy objects.

Collision Avoidance

One of the critical safety concerns in heavy load transportation is the risk of collisions between vehicles, equipment, and workers. Smart robots are designed with advanced sensors, cameras, and machine learning algorithms that enable them to detect obstacles and avoid collisions. These robots can accurately navigate through the workspace, adjusting their routes in real-time to avoid potential hazards. By preventing collisions, smart robots significantly reduce the risk of accidents and injuries in the workplace.

Remote Operation and Monitoring

Smart robots often incorporate remote operation and monitoring capabilities, allowing human operators to control and oversee their movements and tasks from a safe distance. This feature is particularly beneficial in hazardous environments where workers may be exposed to dangerous conditions or materials. By operating robots remotely, workers can avoid direct contact with potential risks, ensuring their safety while still being able to carry out necessary tasks effectively.

Real-Time Data and Analytics

Smart robots are equipped with sensors and cameras that collect real-time data about their surroundings. This data can be analyzed to identify potential safety risks and hazards in the workplace. For example, robots can detect spills, leaks, or other hazardous substances and notify operators or safety personnel immediately. By providing real-time data and analytics, smart robots enable proactive safety measures and prompt response to potential dangers, minimizing the risk of accidents and injuries.

Collaborative Robots (Cobots)

Collaborative robots, also known as cobots, are designed to work alongside human workers, enhancing safety and productivity in heavy load transportation. These robots are equipped with safety features such as force sensors and collision detection systems. When working near humans, cobots automatically reduce their speed or stop completely to prevent accidental collisions. This collaborative approach ensures that workers and robots can work together safely, reducing the risk of accidents and injuries.

Training and Education

Implementing smart robots in heavy load transportation requires proper training and education for workers. Companies that introduce these robotic systems invest in training programs that educate workers on how to operate, interact, and collaborate with the robots safely. By providing comprehensive training, workers become familiar with the capabilities and limitations of the robots, ensuring that they can work alongside them without compromising their own safety.

Conclusion

Smart robots have revolutionized workplace safety in heavy load transportation. Through automation, collision avoidance, remote operation, real-time data, and collaboration, these advanced robotic systems significantly reduce the risk of accidents and injuries. By leveraging the capabilities of smart robots, companies can create safer work environments, protect their workers from potential hazards, and enhance overall productivity and efficiency in heavy load transportation operations.