In the age of global trade, ports are no longer just gateways they are high-pressure nerve centers tasked with managing an immense volume of goods swiftly, safely, and efficiently. With globalization accelerating and consumer demand driving expectations of faster delivery, traditional manual port operations struggle to keep up. Enter robotic transport systems a transformative force reshaping how cargo is moved, monitored, and managed across modern port infrastructure.

The integration of robotics into port logistics marks a crucial shift in maritime operations, offering scalable solutions to age-old problems: bottlenecks, human error, limited labor availability, and safety risks. These intelligent systems are not just about automation they are about precision navigation, real-time decision-making, adaptive routing, and sustainable performance. From unmanned ground vehicles to autonomous quadcopters, robotic transport is redefining the speed, structure, and scalability of port operations in the 21st century.

Robotic Transportation

Robotic transportation refers to the use of autonomous or semi-autonomous machines for moving goods and equipment without human intervention. In port environments, where thousands of containers, pallets, and vehicles need to be coordinated each day, robotics offer unprecedented control and efficiency.

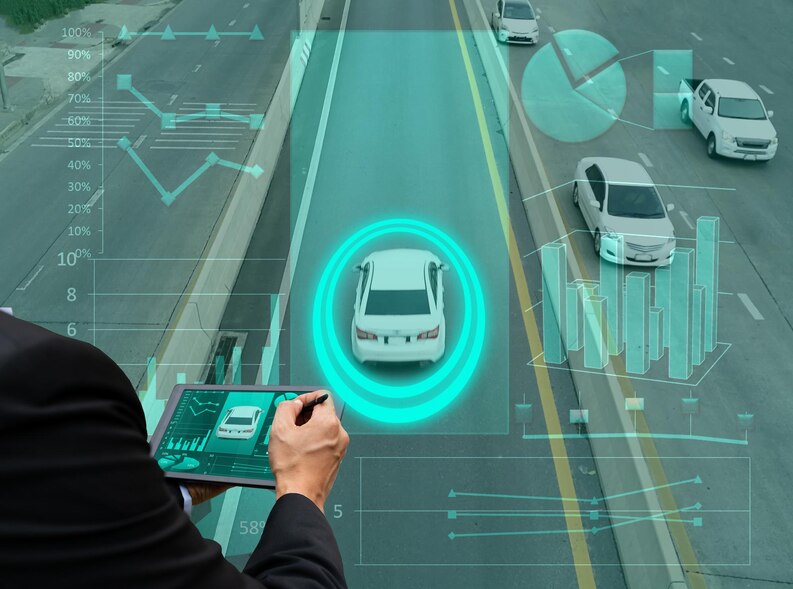

At its core, robotic transportation in logistics revolves around three elements: mobility, intelligence, and interoperability. These machines are designed not only to transport materials across vast container yards but to do so with self-awareness and contextual responsiveness. They leverage advanced sensors, AI-based navigation algorithms, and environmental perception systems to avoid collisions, navigate changing terrain, and optimize routes in real time.

One of the most immediate benefits is reduced dependency on human operators for repetitive and physically taxing tasks, particularly in dangerous environments such as portside loading zones or high-traffic yard lanes. Additionally, robotic transport units can operate around the clock, unaffected by fatigue or shifts, enabling continuous throughput in high-demand periods a game-changer for international trade hubs managing tight shipping schedules.

Robotic Transport System

A robotic transport system in a port setting typically includes a network of interconnected machines and control platforms working in harmony to move goods. This system may consist of:

- Autonomous Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) that move containers between ship decks, cranes, storage areas, and trucks.

- Automated Cranes that precisely lift and place containers without manual input.

- Fleet management software that synchronizes routes, schedules, and tasks across all robotic units.

- Sensor arrays and IoT systems that monitor terrain, weather, and traffic conditions within the port.

What distinguishes an advanced robotic transport system is not just its ability to move objects, but to adapt dynamically to operational conditions. For instance, if a container lane becomes blocked due to a malfunctioning crane, the system reroutes robots in real time to prevent delays. Such adaptability is essential in ports where congestion can result in expensive demurrage charges or cargo rerouting.

Moreover, the system incorporates machine vision and laser-guided navigation technologies for obstacle detection and spatial awareness, enabling robots to operate in shared environments with human workers, forklifts, and other machinery. In doing so, robotic systems contribute to both operational efficiency and safety reducing accidents while accelerating handling times.

Robotics in Port Operations

Ports are rapidly becoming smart logistics hubs, and robotics is central to this transformation. The automation of cargo transport is just one aspect; robotics now plays a role in inspection, maintenance, inventory tracking, and even terminal security.

In major ports such as Rotterdam, Singapore, and Shanghai, autonomous robotic systems are already moving thousands of containers per day. These systems are deeply integrated with terminal operating systems (TOS) and port community platforms to streamline communication between stakeholders and equipment.

The benefits of robotics in port operations include:

- Higher throughput: Autonomous systems maintain consistent performance, maximizing container movement per hour.

- Reduced emissions: Electric-powered robotic transport units lower the carbon footprint compared to diesel-based vehicles.

- Improved traceability: With embedded sensors and GPS, each cargo unit can be tracked in real time, minimizing loss or misplacement.

- Labor optimization: Robotics alleviate pressure on human labor, allowing personnel to focus on high-value, decision-based roles.

- Enhanced safety: Fewer human-machine interactions in hazardous zones reduce injury risks and insurance liabilities.

As labor shortages continue and global shipping volumes increase, the adoption of robotic transport systems is not just a luxury it is rapidly becoming a requirement for maintaining competitive port operations.

Quadcopter Transport

While ground-based robotic systems are the current mainstay of port logistics, quadcopter drones are emerging as a complementary force. These aerial vehicles, equipped with high-definition cameras, sensors, and sometimes even gripping tools, are being tested for a variety of port applications.

In the realm of transport, quadcopters are used for:

- Delivering small, high-priority items between ships and terminals (e.g., customs documents, safety kits, electronic components).

- Inventory scanning in high-bay container storage areas, where traditional access is difficult or time-consuming.

- Monitoring and surveillance, ensuring security across expansive port facilities.

Though not yet widely adopted for heavy cargo movement, the future potential of larger drones and hybrid UAV systems is being actively explored. These platforms could one day perform last-meter deliveries within container yards or serve as emergency responders in accident zones.

Integrating quadcopter transport into port operations presents technical challenges payload limits, battery life, wind conditions but the technological trajectory is clear. As drone flight autonomy, load capacity, and safety compliance improve, quadcopters may soon become indispensable tools for agile, aerial logistics in port ecosystems.

Conclusion

The age of robotic transport in ports is no longer a concept of the future it’s here, active, and evolving rapidly. From autonomous ground vehicles to aerial drones, robotics is reshaping how maritime trade hub’s function, offering unprecedented efficiency, safety, and sustainability.

As global commerce grows more demanding, ports must meet new standards of speed and reliability. Robotic transport systems, fueled by AI, laser navigation, and sensor integration, provide the infrastructure needed to scale. By embracing this technology, ports around the world are not just automating logistics they are building intelligent, resilient, and adaptive supply chains for the decades to come.